INOVA - The Brand For Cantilever Sliding Gates

For more than 40 years, INOVA sliding gates have been a symbol of quality, safety and durability. Thanks to a highly automated production process and our strict quality criteria, our gates last as long as 15 to 20 years. Low follow-up costs for maintenance and repair make our INOVA cantilever swing gates an attractive investment: from the Industrial and Standard lines to our innovative INOVA SilverLine aluminum gates.

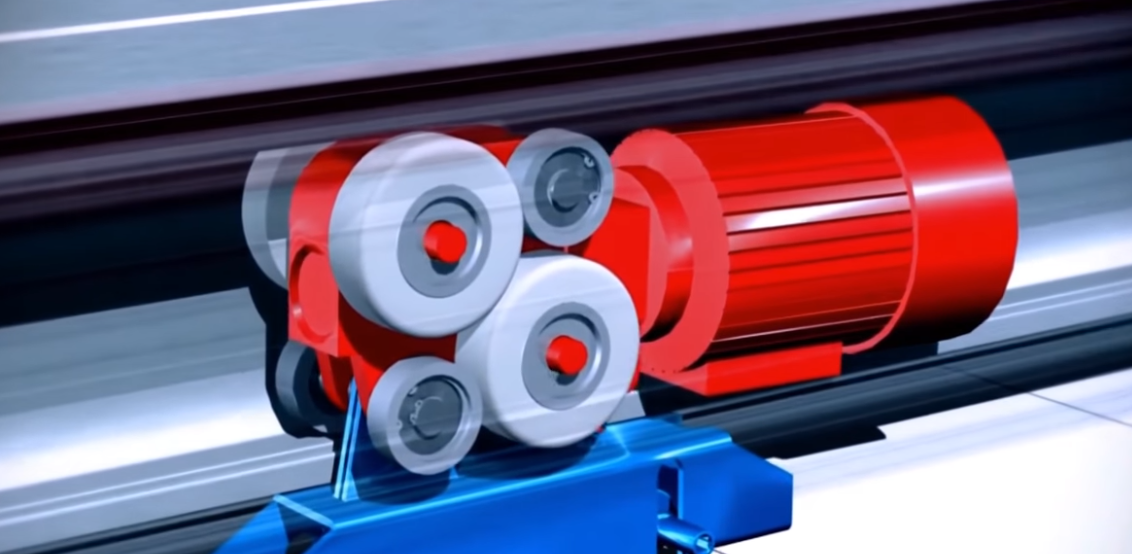

The unique INOVA Sliding Gate Drive System

The INOVA sliding gate drive system is the result of 20 years of excellent engineering skill. All INOVA sliding gates that leave our production site in the German Münsterland region are equipped with an INOVA AC-powered drive.

What makes them so outstanding is the unique design: the drive unit on INOVA cantilever sliding gates – made of steel or aluminum – is housed invisibly inside the lower beam. Beyond its elegant look, the INOVA sliding gate drive includes many more features:

Short Opening Time

The gate opens with a standard speed of up to 0.25 m/s. In the optional high speed mode, the gate can open as fast as 0.5 m/s, depending on the gate size.

Low Operating Costs

We avoid using high-maintenance or sensitive parts such as toothed racks to make our INOVA drives highly wear-resistant and low-maintenance.

Safe Against Vandalism And Manipulation

The drive unit is housed in the gate's lower beam to protect it against the effects of the weather and to make it safe against vandalism and manipulation.

Always Ready For Operation

A sufficient power reserve ensures the reliable operation of INOVA drives even in extreme weather conditions.

Extremely Quiet In Operation

The four high quality drive wheels guarantee an immensely quiet running of the gate, which makes the operation of the sliding gate drive particularly silent.

Your Security Is Our Priority

All automatic INOVA sliding gates are fitted with five active contact strips and two light barriers to offer you the highest security possible. Before a sliding gate leaves our production site, it has to pass full a safety and functioning test. This means all INOVA sliding gates also comply with the applicable standards and directives and are CE marked.

Industrial Sliding Gates

The Industrial sliding gate is renowned for its durability and integrity/adaptability/flexibility. The solid steel construction and powerful AC motor guarantee a reliable operation even with heavy traffic. With a maximum opening width of up to 16 meters (32 m when using two wings) and a variety of optional extra equipment, the Industrial sliding gate leaves nothing to be desired.

Standard Sliding Gate

By choosing the Standard sliding gate you make just the right investment. We always focus on the essential needs of our clients while also maintaining high quality standards. The Standard sliding gate is the ideal solution for many entrances with an average amount of traffic and a maximum opening width of 9 meters. Because our priority is to offer you a secure and durable solution.

INOVA SilverLine

Our SilverLine sliding gate stands out with an elegant aluminum construction. The discreet silver stripes in the upper and lower beam give the SilverLine sliding gate a unique design. Its linear design can be easily integrated in modern construction projects with high architectural standards. The innovative modular construction system ensures an attractive price-performance ratio.

Telescopic Sliding Gate

The telescopic sliding gate is the ideal solution for entrances with limited opening space and the need for maximum opening width. The sliding gate consists of three telescopic leaves of which the middle one is parallel to the outer two gate leaves. This saves up to 30 % of space.

Special Sliding Gates

For more than 40 years Berlemann has been developing and distributing high-quality sliding gate systems. Our experience shows that many projects need sliding gates that are constructed with a certain amount of creativity and high technical standards. Benefit from our skill as specialists for gate construction. We will find the perfect and individual solution for your project.

References

The INOVA sliding gate systems have convinced private clients with high demands, public institutions and many leading commercial and industrial companies. Take a closer look and get an impression of the reference projects we have carried out in close cooperation with our certified INOVA dealers.

Compare INOVA Sliding Gates

The INOVA sliding gate lines offer the right solution for every situation: no matter if you want to secure a high traffic entrance or the sliding gate is opened only sporadically. For every sliding gate you have the choice between manual operation, an electric drive with dead man’s handle control, and an automated electric drive (self-holding) with remote control.

- Basic Equipment

Main areas of application Version Gate leafs Gate column Opening/closing speed Opening width Gate high Lower beam versions* Drive Drive power Duty cycle Surface Standard colours* Gate infills Saftey equipment Key switch One channel remote control Wear strip Clamping Device * Extra equipment available

Industrie Standard SilverLine high-security areas

industrial areas

commercial areasindustrial areas

commercial areascommercial areas

private areascantilevered gates

without floor track

in the passagecantilevered gates

without floor track

in the passagecantilevered gates

without floor track

in the passagesteel, welded steel, welded aluminium, screwed steel, welded aluminium, screwed aluminium, screwed

or steel, weldedapprox. 25 cm/s* approx. 25 cm/s approx. 25cm/s 1-leaf upt to 16 m

2-leaf up to 32 m1-leaf up to 9 m 1-leaf up to 13m up to 2,4m* up to 2 m up to 2,4m 160 mm · 200 mm

280 mm · 400 mm160 mm · 200 mm 200 mm · 240 mm

340 mm · 440 mminternal

INOVA-driveinternal

INOVA-driveinternal

INOVA-drive0,18 kW up to 7 m

0,37 kW up to 10 m

0,75 kW up to 16 m0,18 kW up to 7 m

0,37 kW up to 9 m0,18 kW up to 9 m

0,37 kW up to 13 m100% 100% 70% double

powder coateddouble powder coated anodised or

powder coated6005 Mossgreen

7016 Anthracite grey

7030 Stone grey

9010 Pure white

Inometallic6005 Mossgreen

7016 Anthracite grey

7030 Stone grey

9010 Pure white

Inometallic6005 Mossgreen

7016 Anthracite grey

7030 Stone grey

9010 Pure whitebar infill*

square tube 25bar infill*

square tube 25bar infill

quare tube 302 light barriers

5 active contact strips

Emergency STOP2 light barriers

5 active contact strips

Emergency STOP2 light barriers

5 active contakt strips

Emergency STOPon-site, off-site on-site, off-site on-site, off-site yes yes yes yes * * yes - - - Optional extras

Coating in special colours Intermediate Height Intermediate width Wear strip Serrated Edge Fence connection Reflective warning tape Lateral pedestrian gate Key safe Beacon with rotating LED Flash light Multichannel remote receiver Induction loop Control via card reader Weekly timer Intercom system Additional contact stripes Special gate infills Gate infills on the building side High speed option Soft start Extra performance Brake for gradients Special height >2,4m Control via mobile phone Yearly timer Special control applications, e.g. interlock, traffic light control Link to fire alarm panel Industrie Standard SilverLine yes yes yes yes yes yes yes 0,5 m 0,5 m included yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes yes double wire fence - yes - - yes - - yes - - yes - - yes - - yes - - yes - - yes - - yes - - yes - -

Other optional extra equipment and special designs are available upon request. We will be happy to advise you.

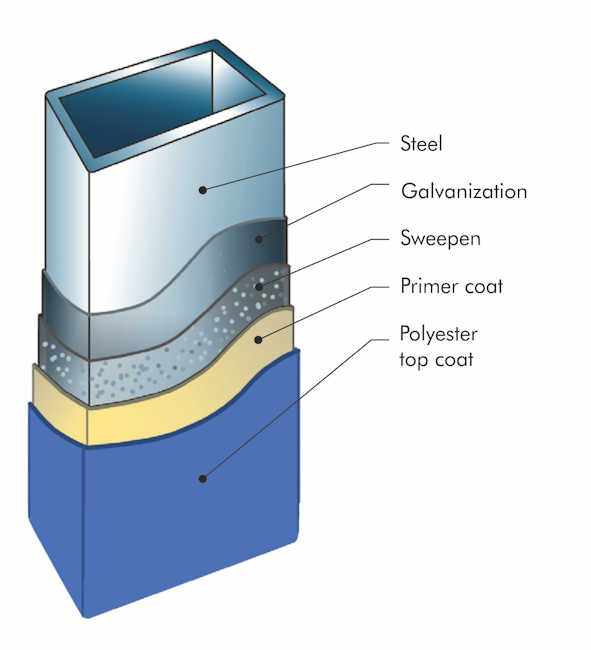

INOVA Triple Corrosion Protection

INOVA steel sliding doors of the lines Industrial and Standard have a threefold protection coating. All steel components are hot dip galvanized according to DIN EN ISO 1461 or sendzimir galvanised. The galvanisation is the basis of the corrosion protection. For long-term corrosion protection an additional double power coating is added. This three-layer treatment is long-lasting, offers a maximum quality of the coating and is environmentally friendly.

To ensure that all INOVA sliding gates leave our factory with perfect powder coating results, the galvanised welded components are carefully examined before the double powder coating is applied.

First, the steel units are cleaned by hand for pretreatment. This eliminates bumps (zinc nibs etc.) that occur especially in hot dip galvanised workpieces.

In the next step, the components are shot-blasted in order to mechanically prepare them for the powder coating. For this treatment, a high-speed stream of rounded and sharp-edge steel particles is directed at the sliding gate. This roughens the gate’s surface and creates a good adhesive bonding to perfectly prepare the gate for the double powder coating.

The INOVA double powder coating consists of an epoxy primer coat and a polyester top coat. The solvent-free powder is applied in an automated coating cabin at our in-house coating unit. Where needed, selected areas are additionally coated by hand. This guarantees perfect coating results.

For the primer coat, the epoxy powder is evenly applied to the gate. Then the sliding gate passes through an industrial furnace. In the furnace, the primer powder coating bakes at a temperature of around 170 °C (340 °F) and forms a 80 µm-thin layer. The primer coat has the following advantages: It serves as an extra corrosion protection in addition to the hot dip galvanisation. It allows good adhesive bonding between the sliding gate surface and the polyester top coat.

In the final step, the gate is coated with the INOVA top coat powder. This coat is highly high resistant against weather and UV as well as to shocks and scratches. These outstanding properties achieved through the use of a high-quality polyester powder, which bakes at 200 °C and then forms a layer with a minimum coating thickness of 80 µm.

In order for INOVA sliding gates to blend in perfectly with any corporate design, we offer our products in any RAL colour. Color requests beyond this colour chart can also be realized at any time. Architects, planners and fencing specialists can be sure that their project will be both a high-quality and a visual highlight.

In the basic specification, we offer the RAL colours 6005 (moss green), 7016 (Anthracite grey), 7030 (Stone grey), 9010 (Pure white) and INOMETALLIC. The INOMETALLIC colour shade is our Berlemann corporate colour, so your gate will blend in perfectly with our other hot dip galvanized connecting elements such as fencing or pedestrian gates.

INOVA Sliding Gate Drive System

Cantilever INOVA Sliding Gates

FAQ

- Sliding gate opener, Sliding gate motor

A unique and award-winning feature of all INOVA sliding gate drive systems is the integration of the sliding gate motor in the lower beam of the sliding gate. This ensures not only an elegant appearance, but also protects the sliding gate opener against weather influences as well as vandalism and manipulation. The integration of the INOVA sliding gate motor is the result of many years of engineering.

- Sliding gate wheels

Sliding gate wheels or rollers are present in INOVA sliding gates, but are practically invisible from the outside.

The sliding gate rollers are part of the drive. There are also sliding gate rollers that act as counter bearings. Means: In order to compensate the enormous forces of a cantilevered sliding gate system, a counter bearing is required.

Sliding gate rollers as part of the drive - Sliding gate design

Our INOVA sliding doors of the series industrie, Standard and SilverLine basically have square tubes as filling. On special request, however, it is possible to build sheet metal or perforated sheet metal into our steel sliding gates as a filling in the door leaf. As a special sliding door, we can prepare the construction for a filling by the customer. Please do not hesitate to ask our experts. We will be happy to advise you.

- Sliding gate track

In connection with sliding gates, tracks and running tracks are always an issue. Modern sliding gates, however, are generally installed and operated in a cantilevered way. INOVA sliding gates are characterised by the fact that they do not require tracks, chains or belts. This offers many advantages in everyday or sporadic door operation. No operator has to ensure that the track, otherwise embedded in the ground, is kept free of snow, ice, leaves or dirt. In addition, there is no need to construct an elaborate strip foundation for the installation. In addition, the internal drive of the INOVA sliding gates ensures an unmistakable smooth running of the door.

![[Translate to Englisch:] Freitragendes INOVA Schiebetor der Standard-Reihe](/fileadmin/default/media/_processed_/e/6/csm_standard_inova_blau-unten_1920x720_50__f28fca0cd1.jpg)